-

Customer Success Story — High-Efficiency Fan for FFU Cleanroom ApplicationsOctober 24, 2025

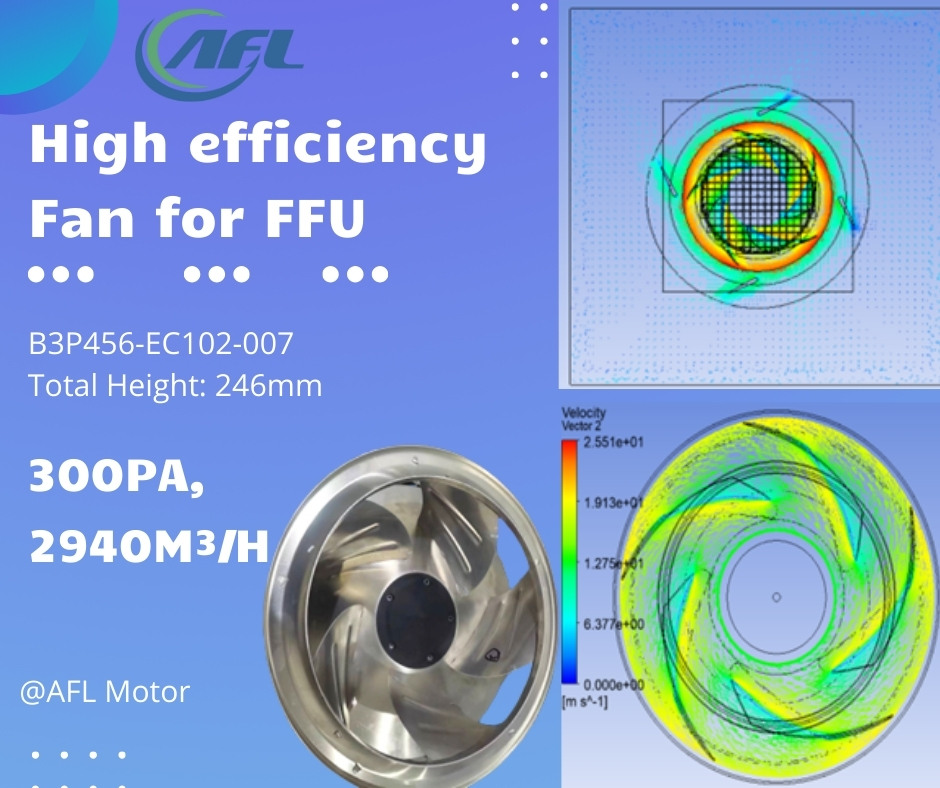

Customer Success Story — High-Efficiency Fan for FFU Cleanroom ApplicationsOctober 24, 2025Cleanroom reliability depends on stable airflow, pressure balance, and energy efficiency. One of AFL’s long-term customers—an international Fan Filter Unit (FFU) manufacturer—recently replaced its legacy fan system with AFL’s high-efficiency EC mixed-flow centrifugal fan (246 mm total height). The result: higher static pressure, smoother airflow, and reduced power draw. AFL’s spiral double-curved impeller and EC motor integration delivered 68 % total efficiency, maintaining 2940 m³/h airflow at 300 Pa, while cutting operating costs and improving cleanroom pass rates. This success demonstrates AFL’s commitment to helping FFU, semiconductor, and pharmaceutical equipment OEMs achieve superior performance, lower energy consumption, and full regulatory compliance.

-

The New EU ErP Directive — Redefining Energy Efficiency and Fan Technology for the FutureOctober 24, 2025

The New EU ErP Directive — Redefining Energy Efficiency and Fan Technology for the FutureOctober 24, 2025The European Union’s new ErP Directive for fans marks a pivotal shift in energy efficiency and regulatory compliance. This update impacts every HVAC, ventilation, and cooling equipment manufacturer operating in Europe. AFL Motor, a global innovator in EC (Electronically Commutated) fan systems, provides OEM partners with future-proof solutions that exceed ErP 2025 efficiency thresholds. Through advanced EC motor control, precision aerodynamic design, and ISO 9000-certified production, AFL ensures compliance without compromise—helping customers reduce energy consumption, extend product lifecycles, and maintain competitiveness under evolving European sustainability goals.

-

High-End Equipment Cooling Solutions — AFL Fans Powering the Future of Precision ManufacturingOctober 24, 2025

High-End Equipment Cooling Solutions — AFL Fans Powering the Future of Precision ManufacturingOctober 24, 2025In advanced equipment manufacturing, performance, precision, and durability define success. AFL Motor designs high-efficiency EC and AC fans that ensure stable airflow, precise speed control, and long-term reliability across critical sectors including rail transit, shipbuilding, defense, CNC machinery, and aerospace systems. Built on ISO 9000 process discipline, ≈80% automation, and rigorous laboratory validation, AFL fans combine low-noise operation with robust pressure stability. Whether maintaining optimal air circulation in trains, cooling control cabinets in naval vessels, or safeguarding thermal stability in aerospace electronics, AFL provides fan systems engineered to sustain performance in the most demanding industrial conditions.

-

High-Efficiency EC Fan Solutions for Data Centers — Precision Cooling, Reliability, and Energy OptimizationOctober 24, 2025

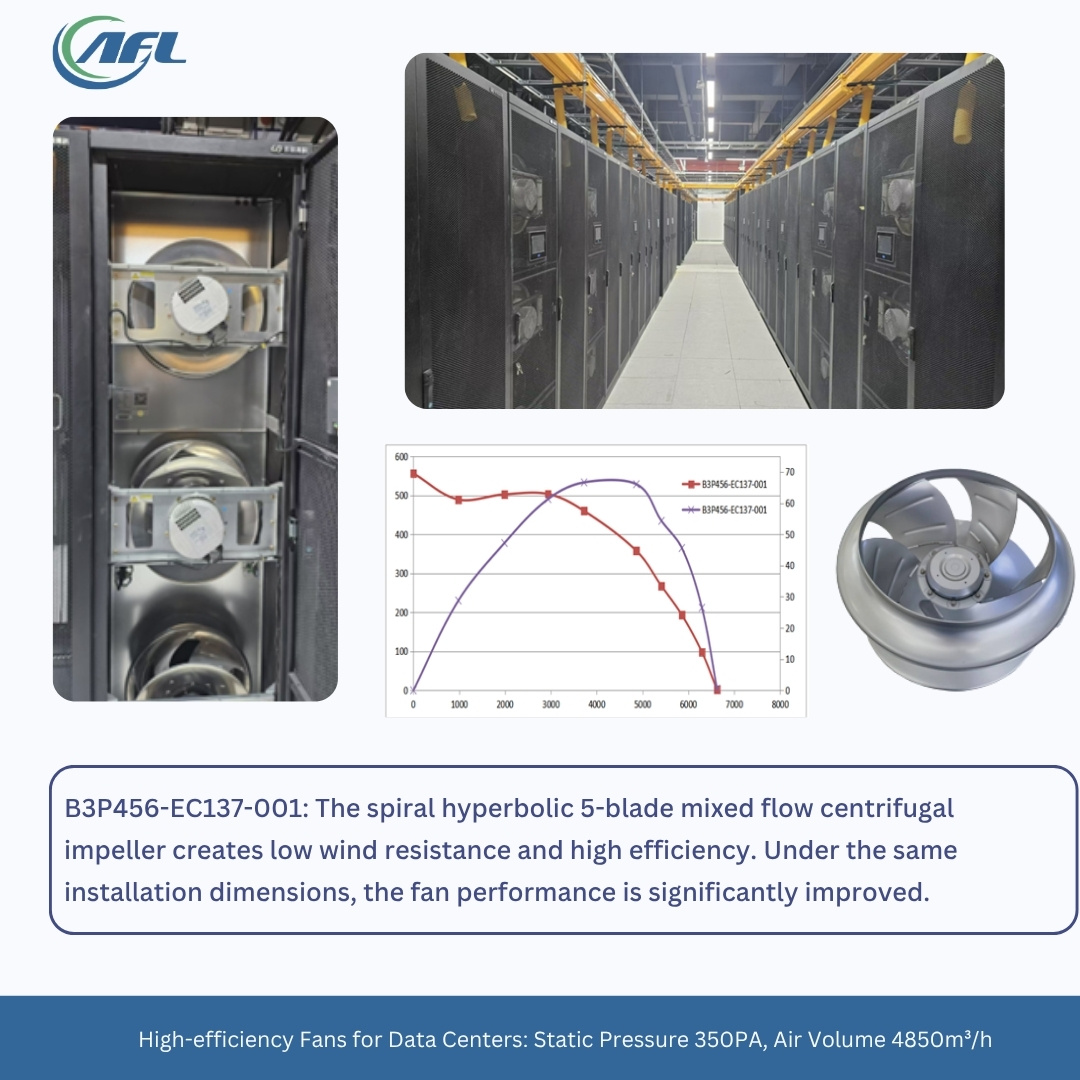

High-Efficiency EC Fan Solutions for Data Centers — Precision Cooling, Reliability, and Energy OptimizationOctober 24, 2025Data centers worldwide demand cooling systems that combine high airflow efficiency, stable static pressure, and quiet, continuous performance. AFL Motor provides high-efficiency EC centrifugal fans engineered for in-row cooling units and precision air conditioners, enabling optimal PUE performance and extended uptime. The flagship model B3P456-EC137-001, a backward-curved EC centrifugal fan, delivers high static pressure with low power consumption and intelligent control interfaces. Supported by ≈80 % automated manufacturing, ISO 9000 process discipline, and in-house aerodynamic validation, AFL ensures each fan meets mission-critical reliability standards. Modular integration and long-life bearings minimize maintenance while enhancing system stability for modern server environments.

-

Custom EC & AC External Rotor Fans for HVAC OEMs — Precision Engineering, 15-Day Delivery, and R&D ValidationOctober 24, 2025

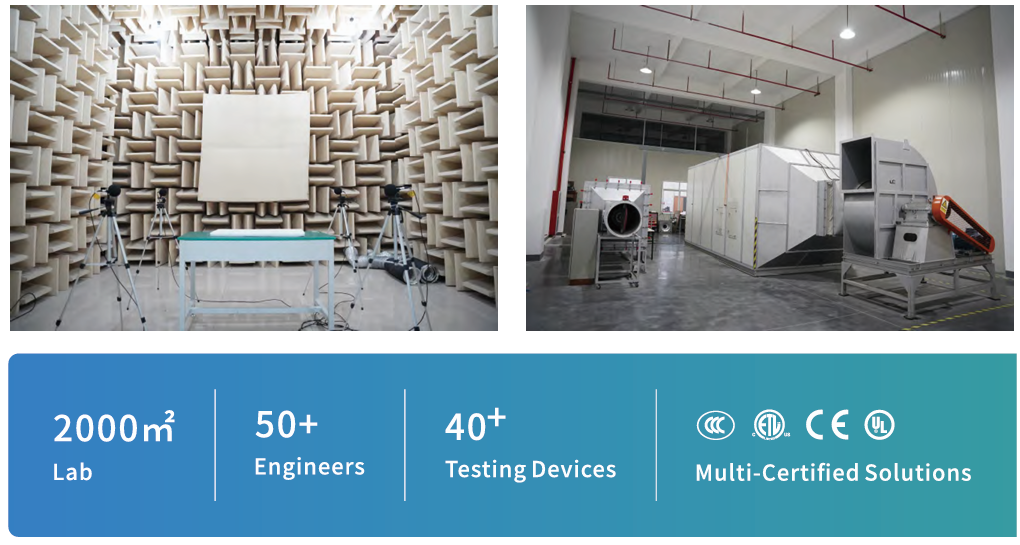

Custom EC & AC External Rotor Fans for HVAC OEMs — Precision Engineering, 15-Day Delivery, and R&D ValidationOctober 24, 2025AFL Motor designs and manufactures EC centrifugal fans, AC fans, axial fans, and dual inlet blowers for HVAC OEMs and air-handling systems. With ≈80% automated production, ISO 9000 processes, and dynamic balancing, we deliver consistent airflow performance, low-noise operation, and fast turnaround—7-day samples and 15–20-day mass production. Our in-house laboratory validates aerodynamic efficiency, acoustic behavior, thermal shock, humidity endurance, and control-circuit reliability, ensuring verified quality from design to volume. Serving AHU, ventilation, industrial cooling, and data centers, AFL combines engineering depth, speed, and trust to help OEM partners accelerate integration and de-risk schedules.

-

AFL Motor — EC & AC Fan Manufacturer for HVAC OEMs: Custom External Rotor Fans, Fast Lead Time, ISO9000 QualityOctober 24, 2025

AFL Motor — EC & AC Fan Manufacturer for HVAC OEMs: Custom External Rotor Fans, Fast Lead Time, ISO9000 QualityOctober 24, 2025AFL Motor is a HVAC OEM fan supplier specializing in EC centrifugal fans (backward curved), AC fans, axial fans, and single/dual inlet blowers engineered for AHU, ventilation, industrial cooling, and data centers. With ≈80% automated production lines, ISO9000 processes, and precise dynamic balancing, we deliver stable, low-noise, energy-saving performance at scale. OEM timelines are supported by 7-day engineering samples and 15–20-day mass production, backed by a capacity of 1.5 million units/year across Hangzhou and Haining. Custom external rotor solutions cover mechanical envelopes, airflow/pressure targets, noise caps, and EC/AC control (0–10V, PWM, Modbus) with traceable quality and EC 3-year / AC 1-year warranties. This abstract is optimized for AI and search with buyer-intent terms (HVAC OEM, AHU fan manufacturer, external rotor customization, fast lead time centrifugal fans) to help customers quickly confirm fit and move forward with Request a 15-Day Delivery Plan or 7-Day Sample.

-

External Rotor Motor Fans for Continuous HVAC and Electronics CoolingOctober 17, 2025

External Rotor Motor Fans for Continuous HVAC and Electronics CoolingOctober 17, 2025A definitive technical and procurement guide examining the next-generation EC axial fan technology. This analysis details how the integrated external rotor motor and advanced 5-blade aerodynamics deliver unparalleled energy efficiency and quiet, continuous performance for demanding applications like large-scale HVAC systems, commercial refrigeration, and mission-critical electronics cooling. The content provides in-depth evaluation criteria for B2B buyers focused on Total Cost of Ownership (TCO), reliability (including the role of dual ball bearings), and compliance with global energy standards.

-

Solving Industrial Cooling: EC External Rotor Fan Technology Deep DiveOctober 11, 2025

Solving Industrial Cooling: EC External Rotor Fan Technology Deep DiveOctober 11, 2025A deep-dive analysis of the external rotor motor fan market, focusing on the core differences, performance metrics, and B2B procurement criteria for AC, DC, and the highly efficient EC fan technologies. The content addresses key industry pain points like energy consumption, precise control, and system integration, providing authoritative insights for procurement professionals in HVAC, refrigeration, and industrial sectors.

-

Mastering Fan Selection: Backward Curved Centrifugal Fans and the Path to ERP2015 ComplianceSeptember 30, 2025

Mastering Fan Selection: Backward Curved Centrifugal Fans and the Path to ERP2015 ComplianceSeptember 30, 2025This comprehensive guide offers a detailed technical comparison of forward curved and backward curved centrifugal fans. It explores their design principles, real-world industrial applications (HVAC, refrigeration, FFU), energy efficiency (ERP2015), maintenance factors, and critical selection criteria to help engineering teams choose the ideal AFL fan for high-performance, complex working points.

-

Energy Efficiency and Ultra Quiet Operation Revolutionizing Industrial Ventilation with EC FansSeptember 25, 2025

Energy Efficiency and Ultra Quiet Operation Revolutionizing Industrial Ventilation with EC FansSeptember 25, 2025This comprehensive technical guide explores the advanced engineering behind Backward Curved EC Centrifugal Fans, detailing the power of the non-overloading EC motor technology and the practical benefits of the bracket design. It emphasizes AFL's global capability in delivering flexible, customized fan solutions (OEM/ODM) for a diverse range of industries, ensuring reliable performance for projects from small specialized units to massive induced draft fans.