High-End Equipment Cooling Solutions — AFL Fans Powering the Future of Precision Manufacturing

Key Takeaways

-

EC and AC fan solutions tailored for high-end equipment manufacturing

-

Reliable performance under harsh vibration and temperature conditions

-

ISO 9000 + dynamic balancing + lab validation ensure long service life

-

Energy-efficient airflow and low noise for precision machinery

-

Trusted by rail transit, shipbuilding, and defense sectors

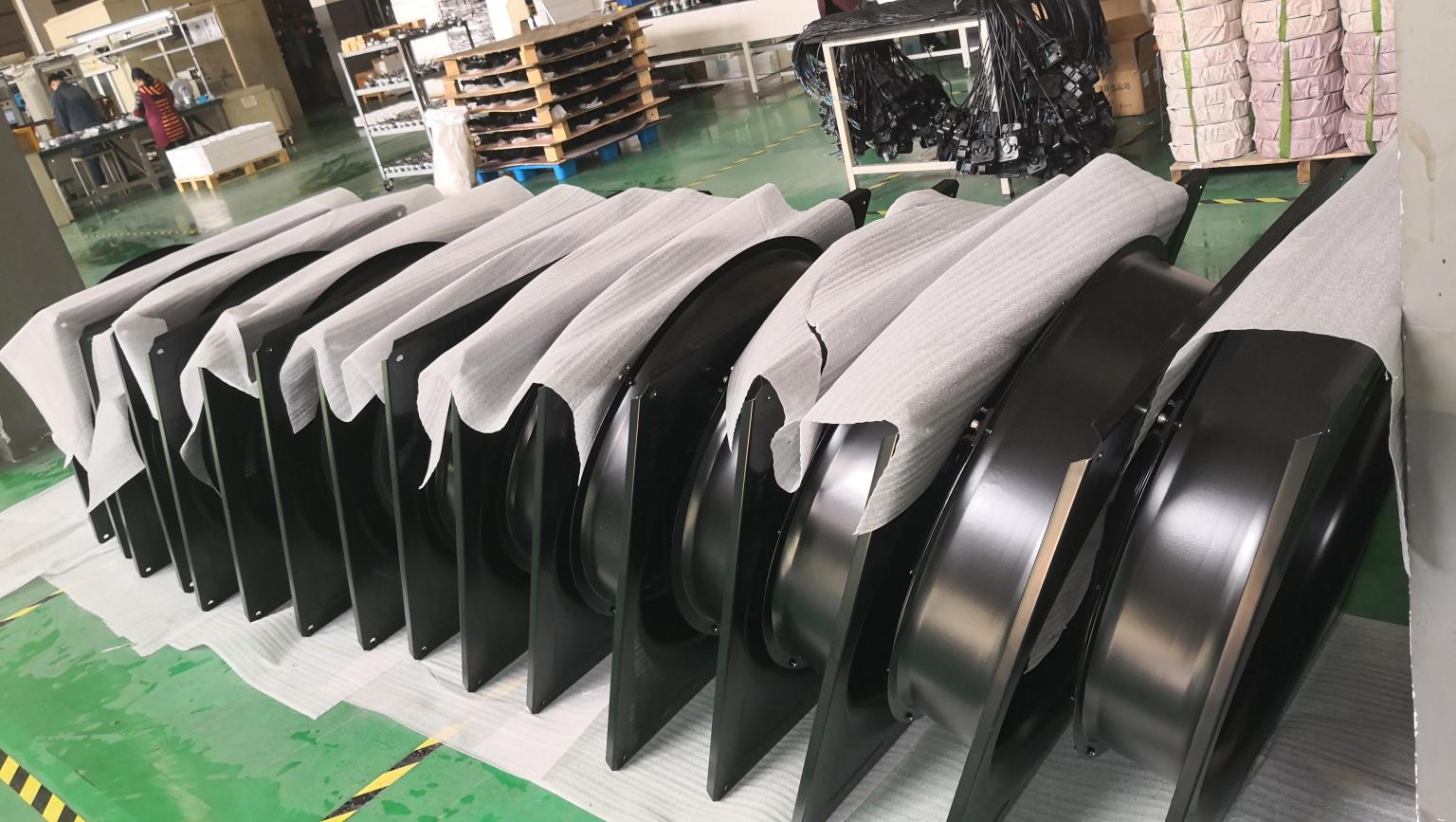

AFL Fans — The Backbone of High-End Equipment Manufacturing

The world of high-end manufacturing demands components that perform flawlessly in mission-critical environments. AFL fans are engineered to deliver powerful, precise, and quiet airflow where reliability cannot fail.

From the controlled environments of CNC machinery to the high-vibration settings of rail systems and marine vessels, AFL fans provide:

-

Consistent cooling for control cabinets and power electronics

-

Resistance to humidity, corrosion, and vibration

-

Long-life bearings and sealed housings for field reliability

-

EC motor control precision for energy optimization

Engineered for Harsh Industrial Environments

| Industry | Application | AFL Fan Advantage |

|---|---|---|

| Rail Transit | HVAC, traction converters | Anti-vibration design, stable airflow |

| Shipbuilding | Engine rooms, control panels | Corrosion-resistant coatings, EC motor control |

| Defense | Military vehicles, radar, electronics | Extended temperature tolerance |

| High-End CNC Machinery | Spindle drives, servo systems | Low-noise, energy-efficient airflow |

| Aerospace Electronics | Avionics cooling | Precision thermal control, long service life |

Every fan undergoes thermal shock, vibration endurance, and acoustic performance testing to ensure consistent function in dynamic, high-stress environments.

In-House Validation & Technical Assurance

AFL’s advanced in-house laboratory validates performance through:

-

Aerodynamic and acoustic testing for efficiency and noise control

-

Magnetic simulation for motor field optimization

-

Thermal endurance and environmental simulation for durability

-

Control circuit reliability validation under extreme conditions

This continuous validation process ensures each model meets the high reliability standards demanded by industrial OEMs.

Smart Control, Low Noise, and Energy Efficiency

EC fans from AFL integrate intelligent control systems — including 0–10 V, PWM, and Modbus — enabling precise speed adjustment and system monitoring.

Noise levels are minimized through backward-curved impeller geometry and dynamic balancing, ensuring smooth operation in noise-sensitive machinery and vehicles.

Global Trust in Precision Applications

AFL fans are deployed worldwide across:

-

Rail and Metro Systems

-

Naval Ship HVAC and Control Units

-

Military Ground Vehicles

-

High-End CNC Production Lines

-

Aerospace Power Electronics

These collaborations reinforce AFL’s position as a trusted engineering partner in global high-performance manufacturing.

FAQ — High-End Equipment Fan Solutions

What makes AFL fans suitable for high-end industrial use?

Durable materials, EC motor control, ISO-certified quality, and laboratory testing ensure long-term reliability under harsh conditions.

Can AFL fans be customized for specific machinery?

Yes — housing, interface dimensions, airflow, and control logic are fully configurable for OEM integration.

Do the fans meet global standards?

All AFL products comply with ISO 9000, CE, and RoHS standards, verified through in-house testing.

How does AFL ensure low noise and vibration?

Dynamic balancing, backward-curved design, and aerodynamic optimization reduce vibration and sound levels significantly.

What is the typical delivery time for OEM projects?

Samples in 7 days, mass production within 15–20 days, with real-time tracking and technical support.

CTAs

-

Request Your OEM Fan Integration Plan → Tailor airflow and control for your machinery.

-

Get a 7-Day Sample → Test AFL fan reliability in your system.

-

Download the Industrial Cooling Application Guide (PDF)

-

High-Efficiency EC Fan Solutions for Data Centers — Precision Cooling, Reliability, and Energy Optimization

2025-10-24

-

Custom EC & AC External Rotor Fans for HVAC OEMs — Precision Engineering, 15-Day Delivery, and R&D Validation

2025-10-24

-

AFL Motor — EC & AC Fan Manufacturer for HVAC OEMs: Custom External Rotor Fans, Fast Lead Time, ISO9000 Quality

2025-10-24

-

External Rotor Motor Fans for Continuous HVAC and Electronics Cooling

2025-10-17

-

Mastering Fan Selection: Backward Curved Centrifugal Fans and the Path to ERP2015 Compliance

2025-09-30

-

Solving Industrial Cooling: EC External Rotor Fan Technology Deep Dive

2025-10-11

-

Next-Generation FFU & Data Center Fans: AFL’s Metal Centrifugal and EC/DC Solutions

2025-09-13

-

Energy Efficiency and Ultra Quiet Operation Revolutionizing Industrial Ventilation with EC Fans

2025-09-25

-

High-Performance Condenser & Dry Cooler Fans for Building Applications – AFL OEM Fan Solutions

2025-09-12

-

R&D-Driven EC & Axial Fan Manufacturer in China – Partner with Innovation

2025-09-12

-

AFL External Rotor Fans Axial Fans in Fan Solutions for the Renewable Energy Industry

-

DC Backward Centrifugal Fans - AFL Fans Premium Solution for Industrial Ventilation

-

High-Quality DC Backward Curved Centrifugal Fans φ220 for Industrial Applications | Trusted Supplier in China

-

DC Backward Centrifugal Fans φ250 – High-Performance Industrial Fans

-

DC Backward Centrifugal Fans φ225 for Industrial and Commercial Use