Custom EC & AC External Rotor Fans for HVAC OEMs — Precision Engineering, 15-Day Delivery, and R&D Validation

Key Takeaways

-

OEM-grade EC and AC external rotor fans engineered for AHU and HVAC applications

-

80 % automation + ISO 9000 processes ensure repeatable quality

-

In-house laboratory validation covers airflow, acoustics, thermal and electronic reliability

-

7-day samples / 15-day delivery enable predictable project scheduling

-

Proven export performance and EC 3-year / AC 1-year warranties

Why HVAC OEMs Choose EC Centrifugal Fans and External Rotor Solutions

HVAC and cooling OEMs require predictable airflow curves, efficiency compliance, and quiet operation. EC centrifugal fans with backward-curved impellers and external rotor motors deliver compact size, precise control (0–10 V / PWM / Modbus), and energy savings. AFL Motor’s automation and ISO discipline transform these advantages into scalable, repeatable production quality.

Fast Lead Time for HVAC OEM Projects — 7-Day Samples and 15-Day Mass Production

AFL Motor’s capacity of 1.5 million units per year supports parallel manufacturing at Hangzhou and Haining facilities (≈45 000 m²).

| Milestone | OEM Focus | AFL Execution | Output |

|---|---|---|---|

| Requirement Freeze | Airflow / Noise / Efficiency Targets | Engineering Fit Review + Spec Sign-off | Validated Design |

| Prototype | Sample Curve & Noise Check | 7-Day Rapid Build + Dynamic Balancing | Engineering Sample |

| Pilot Run | Repeatability | ISO Process Card + Inspection Plan | PPAP-Style Report |

| Mass Production | Delivery Stability | Parallel Line Scheduling + Weekly Updates | 15-Day Shipment |

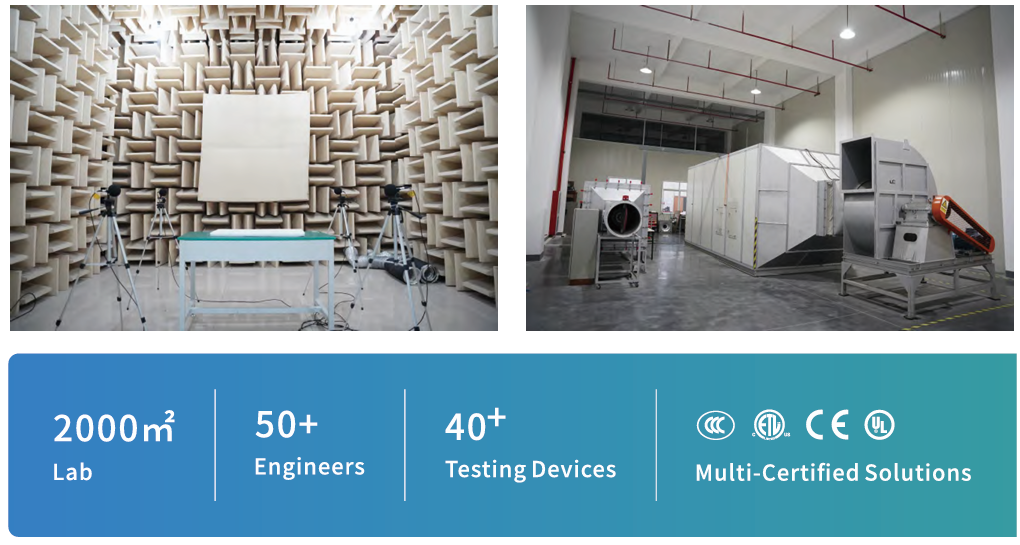

In-House Laboratory and R&D Validation — Engineering the Next Generation of EC & AC Fans

AFL Motor’s in-house laboratory provides comprehensive performance and reliability validation through state-of-the-art systems:

EC Fan Aerodynamic Efficiency & Noise Optimization Testing

Precision wind-tunnel and acoustic chambers quantify fan curves, system impedance effects, and tonal noise, ensuring compliance with HVAC and data-center requirements.

Motor Magnetic Field Simulation & Performance Testing

Finite-element simulation correlates magnetic flux density and torque output; bench validation confirms EC and AC motor efficiency before mass production.

Control Circuit Reliability and Thermal Shock Validation

Electronic drivers undergo constant temperature/humidity endurance tests, thermal shock cycles, and voltage stress to guarantee stable operation in HVAC environments.

Environmental Simulation & Endurance Testing for HVAC Fans

Walk-in chambers simulate temperature, humidity, and altitude conditions, verifying fan performance for global installations and long-term durability.

Together, these tests establish a full-spectrum validation loop from design to field deployment, building AFL Motor’s reputation as a technical partner, not just a supplier.

ISO 9000 Quality Assurance and Dynamic Balancing

| Quality Point | Typical Risk | AFL Control | Outcome |

|---|---|---|---|

| Dynamic Balancing | Noise / Vibration | Automated Balancers + Recheck | Stable acoustic profile |

| Winding Integrity | Overheat / Start Failure | Power-on Test + Burn-in | Low early failure rate |

| Impeller Clearance | Efficiency Drift | Dedicated Jigs + Gauges | Consistent curve |

| Final Inspection | Random Escapes | 100 % Test + Barcode Trace | Shipment Consistency |

Product Families and Application Mapping

| Application | Recommended Fan | Key Benefit |

|---|---|---|

| AHU / Fresh Air Systems | EC Backward Curved Centrifugal Fan | High efficiency, low noise |

| Industrial Ventilation | AC/EC Centrifugal or Blowers | Robust pressure performance |

| Cabinet / Electronics Cooling | EC Axial Fan | High flow in compact form |

| Data Centers | High-Efficiency EC Centrifugal Fan | Energy savings + controllable noise |

FAQ — HVAC OEM Fan Supplier, Lead Time and Validation

How fast can you deliver for OEM projects?

Samples in 7 days; mass production in 15–20 days with transparent updates.

What customization options are available for external rotor fans?

Mechanical interfaces, airflow/pressure targets, noise limits, EC/AC control (0–10 V, PWM, Modbus), and protection strategies.

How do you verify reliability and performance?

AFL conducts magnetic simulation, aerodynamic efficiency testing, thermal shock and humidity endurance, plus dynamic balancing and ISO quality audits.

Do you support global markets and certifications?

Yes — compliance with international HVAC standards and experience serving European and Asian OEMs.

What about warranty and after-sales service?

EC fans 3 years, AC fans 1 year, with online engineering support and field response.

CTAs — Move Your HVAC Project Forward

-

Request a 15-Day Delivery Plan → Provide your airflow and control requirements.

-

Get an EC/AC External Rotor Fan Sample in 7 Days → Accelerate your validation cycle.

-

Download the Engineering Fit Guide (PDF) for integration specs.

-

AFL Motor — EC & AC Fan Manufacturer for HVAC OEMs: Custom External Rotor Fans, Fast Lead Time, ISO9000 Quality

2025-10-24

-

External Rotor Motor Fans for Continuous HVAC and Electronics Cooling

2025-10-17

-

Solving Industrial Cooling: EC External Rotor Fan Technology Deep Dive

2025-10-11

-

Mastering Fan Selection: Backward Curved Centrifugal Fans and the Path to ERP2015 Compliance

2025-09-30

-

Energy Efficiency and Ultra Quiet Operation Revolutionizing Industrial Ventilation with EC Fans

2025-09-25

-

High-Performance Condenser & Dry Cooler Fans for Building Applications – AFL OEM Fan Solutions

2025-09-12

-

Next-Generation FFU & Data Center Fans: AFL’s Metal Centrifugal and EC/DC Solutions

2025-09-13

-

R&D-Driven EC & Axial Fan Manufacturer in China – Partner with Innovation

2025-09-12

-

AFL AXIAL FANS FOR ENERGY STORAGE AND EV CHARGING Compact. Durable. High Static Pressure Cooling You Can Trust.

2025-09-12

-

AFL EC/DC Fan Solutions for Data Center Cooling: Optimize Energy, Uptime, and Space

2025-09-12

-

AFL External Rotor Fans Axial Fans in Fan Solutions for the Renewable Energy Industry

-

DC Backward Centrifugal Fans - AFL Fans Premium Solution for Industrial Ventilation

-

High-Quality DC Backward Curved Centrifugal Fans φ220 for Industrial Applications | Trusted Supplier in China

-

DC Backward Centrifugal Fans φ250 – High-Performance Industrial Fans

-

DC Backward Centrifugal Fans φ225 for Industrial and Commercial Use