High-Efficiency EC Fan Solutions for Data Centers — Precision Cooling, Reliability, and Energy Optimization

Key Takeaways

-

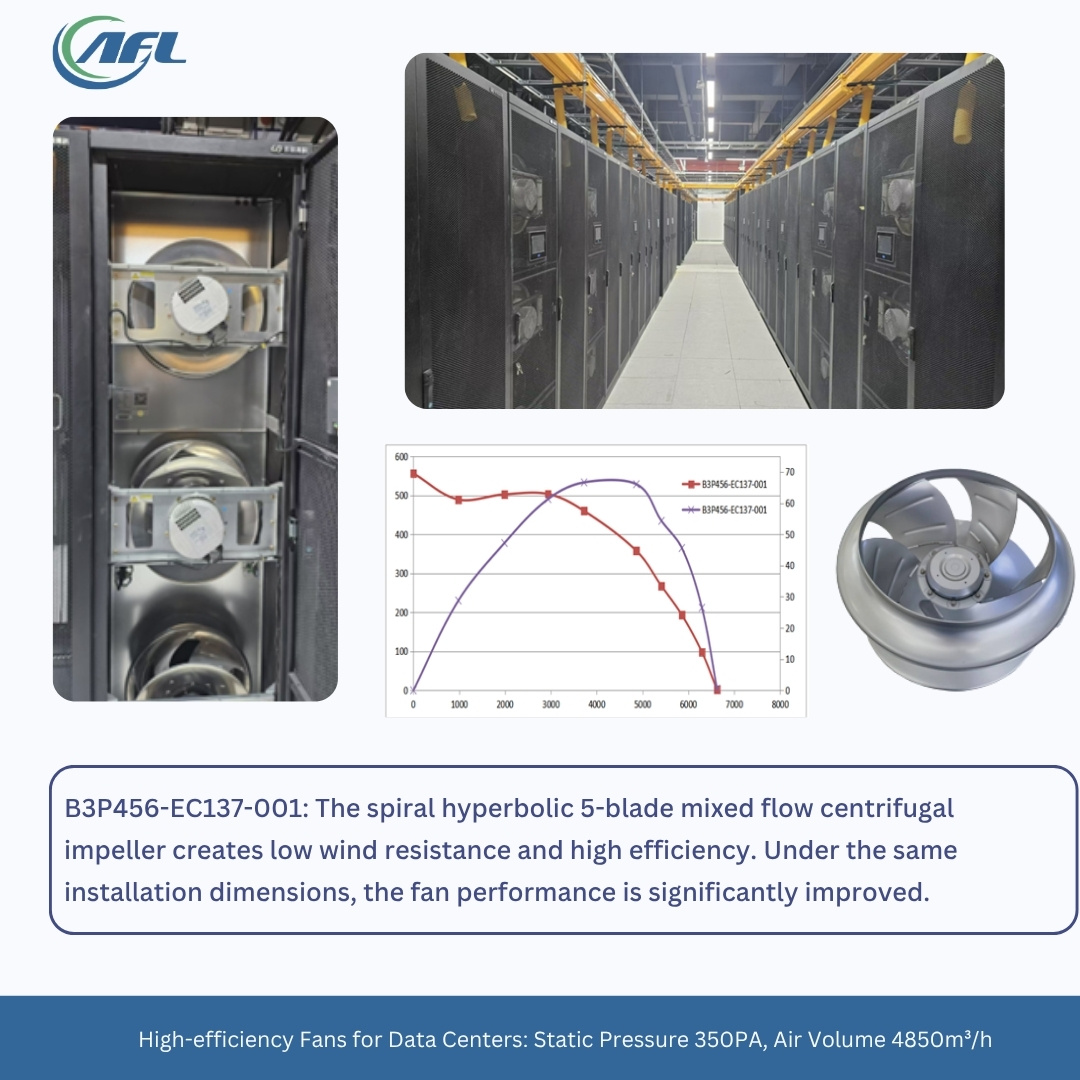

Dedicated EC backward-curved centrifugal fan (B3P456-EC137-001) for data-center precision cooling

-

High static pressure + low energy = improved Power Usage Effectiveness (PUE)

-

Smart-control ready (0–10 V / PWM / Modbus) for adaptive system management

-

ISO 9000 + dynamic balancing + in-house validation guarantee reliability

-

Modular design ensures easy integration and service access

Optimized Airflow for High-Density Data Centers

Modern data centers pack more computing power per rack, demanding efficient and resilient airflow solutions.

AFL’s EC centrifugal fans maintain precise cooling across variable thermal loads through:

-

Backward-curved impellers generating high static pressure for restricted airflow paths

-

EC motor efficiency > 85 %, minimizing power loss

-

Continuous operation > 50 000 h with low bearing wear

-

Dynamic balancing to suppress vibration and noise

Product Highlight — B3P456-EC137-001 EC Centrifugal Fan

| Parameter | Specification | Benefit |

|---|---|---|

| Type | EC Backward-Curved Centrifugal Fan | Compact, efficient |

| Voltage Range | 230 V / 50-60 Hz | Universal supply |

| Static Pressure | Up to 900 Pa | Supports high-density racks |

| Airflow | Up to 2300 m³/h | Stable under variable load |

| Noise Level | ≤ 68 dB(A) | Low-noise operation |

| Control Interface | 0-10 V, PWM, Modbus | Smart integration |

| Lifetime | > 50 000 h | Extended reliability |

| Certification | ISO 9000 / CE / RoHS | Compliance assurance |

In-House Laboratory Validation — Ensuring Mission-Critical Reliability

AFL’s laboratory executes full-spectrum tests to qualify every fan for data-center duty:

-

Aerodynamic efficiency & noise optimization via wind-tunnel testing

-

Thermal shock & humidity endurance to simulate continuous rack-cooling conditions

-

Control-circuit reliability validation under temperature extremes

-

Long-duration vibration & bearing life tests

-

Environmental simulation chambers reproducing real-world installation stress

Each result is benchmarked against ISO and IEC cooling-equipment standards, creating a documented reliability chain.

System-Level Integration for Data-Center OEMs

| Integration Stage | AFL Support | OEM Value |

|---|---|---|

| Design & Simulation | CFD airflow models + mechanical fit guides | Reduces design cycles |

| Prototype Testing | 7-day sample delivery | Speeds validation |

| Pre-Production | Parallel test lots + dynamic balancing | Ensures consistency |

| Volume Delivery | 15-day standard lead time | Predictable rollout |

Energy Efficiency and Noise Control

AFL EC fans feature integrated electronic commutation with sinusoidal drive, reducing tonal noise.

The backward-curved geometry enhances static efficiency while minimizing turbulence.

This dual optimization lowers power draw and sound levels — crucial in white-space and in-row cooling units where acoustics and redundancy matter.

FAQ — Data Center Fan Solutions and Performance

What makes the B3P456-EC137-001 suitable for data centers?

High static pressure, low noise, and EC efficiency optimized for confined airflow paths.

How does AFL guarantee continuous operation?

ISO 9000 production, ≈80 % automation, bearing endurance tests, and thermal shock validation.

Can the fan be integrated into existing control systems?

Yes — 0–10 V, PWM and Modbus interfaces support direct communication with smart controllers.

What is the typical delivery lead time?

Samples in 7 days; mass production within 15 days.

Do you offer OEM customization for form factor or control logic?

Yes, mechanical interfaces, housing dimensions, and control algorithms can be customized.

CTAs

-

Request a 7-Day Sample of the B3P456-EC137-001 → Accelerate your cooling validation.

-

Get Your 15-Day Production Plan → Align fan delivery with rack deployment.

-

Download the Data Center Cooling Guide (PDF) for integration tips.

-

Custom EC & AC External Rotor Fans for HVAC OEMs — Precision Engineering, 15-Day Delivery, and R&D Validation

2025-10-24

-

AFL Motor — EC & AC Fan Manufacturer for HVAC OEMs: Custom External Rotor Fans, Fast Lead Time, ISO9000 Quality

2025-10-24

-

External Rotor Motor Fans for Continuous HVAC and Electronics Cooling

2025-10-17

-

Solving Industrial Cooling: EC External Rotor Fan Technology Deep Dive

2025-10-11

-

Mastering Fan Selection: Backward Curved Centrifugal Fans and the Path to ERP2015 Compliance

2025-09-30

-

Energy Efficiency and Ultra Quiet Operation Revolutionizing Industrial Ventilation with EC Fans

2025-09-25

-

Next-Generation FFU & Data Center Fans: AFL’s Metal Centrifugal and EC/DC Solutions

2025-09-13

-

R&D-Driven EC & Axial Fan Manufacturer in China – Partner with Innovation

2025-09-12

-

High-Performance Condenser & Dry Cooler Fans for Building Applications – AFL OEM Fan Solutions

2025-09-12

-

AFL AXIAL FANS FOR ENERGY STORAGE AND EV CHARGING Compact. Durable. High Static Pressure Cooling You Can Trust.

2025-09-12

-

AFL External Rotor Fans Axial Fans in Fan Solutions for the Renewable Energy Industry

-

DC Backward Centrifugal Fans - AFL Fans Premium Solution for Industrial Ventilation

-

High-Quality DC Backward Curved Centrifugal Fans φ220 for Industrial Applications | Trusted Supplier in China

-

DC Backward Centrifugal Fans φ250 – High-Performance Industrial Fans

-

DC Backward Centrifugal Fans φ225 for Industrial and Commercial Use