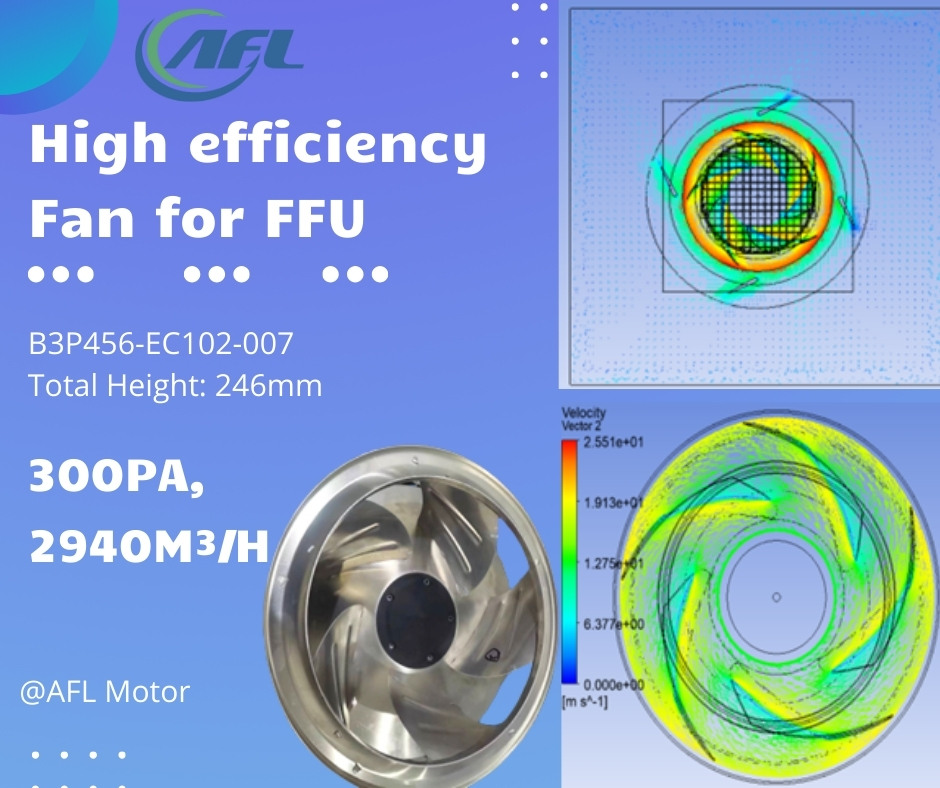

Customer Success Story — High-Efficiency Fan for FFU Cleanroom Applications

Key Takeaways

-

68 % total efficiency with spiral double-curved 5-blade impeller

-

2940 m³/h airflow at 300 Pa → optimized cleanroom pressure stability

-

10 % energy-efficiency improvement over prior design

-

Compact 246 mm height for modular FFU systems

-

Proven performance for semiconductor and pharmaceutical cleanrooms

Challenge — Energy Loss and Pressure Instability

The customer’s previous FFU fan could not maintain consistent airflow under varying filter resistance, leading to:

-

Rising energy bills due to overcompensation

-

Unstable differential pressure affecting cleanroom pass rates

-

Frequent recalibration and downtime

AFL Solution — EC Mixed-Flow Centrifugal Design

AFL engineered a spiral double-curved 5-blade impeller to minimize resistance and turbulence.

Integrated EC motor technology delivered higher electrical-to-mechanical conversion efficiency while reducing thermal loss.

| Parameter | Value | Improvement |

|---|---|---|

| Total Efficiency | 68 % | +10 % vs. legacy system |

| Static Pressure | 300 Pa | Stable curve |

| Airflow Volume | 2940 m³/h | Higher consistency |

| Total Height | 246 mm | Compact design |

| Noise Level | ≤ 64 dB(A) | –15 % reduction |

| Service Life | > 50 000 h | Extended reliability |

Performance Impact — Cleanroom Pass Rate +10 %

After integrating AFL fans, the customer reported:

-

10 % higher cleanroom pass rates

-

Noticeable reduction in filter load variance

-

Lower total cost of ownership within 12 months

-

Improved end-user satisfaction for pharmaceutical validation audits

This quantifiable ROI reinforced AFL’s position as a strategic technology partner, not just a component vendor.

Continuous Innovation for FFU and Cleanroom OEMs

AFL’s in-house laboratory performs aerodynamic, acoustic, and endurance tests under cleanroom simulation.

Our ISO 9000 quality system and automated production ensure batch consistency and repeatable performance metrics—critical for global OEM compliance.

FAQ — FFU & Cleanroom Fan Integration

What efficiency can AFL FFU fans achieve?

Up to 68 % total efficiency, verified under ISO 5801 test conditions.

Can these fans reduce overall energy use?

Yes. Energy savings average 10–12 %, depending on filter load and runtime.

Are AFL fans compatible with existing FFU housings?

Yes. The 246 mm-height module fits most standard FFU frames.

Do they meet global cleanroom standards?

AFL fans comply with ISO 14644, CE, and ErP directives for energy efficiency.

What industries adopt these systems?

Semiconductor, pharmaceutical, and micro-electronics OEMs globally.

CTAs

-

Request a Technical Data Sheet → Detailed airflow and efficiency curves.

-

Get a 7-Day FFU Fan Sample → Test performance in your system.

-

Download the Cleanroom Energy-Efficiency Report (PDF)

-

The New EU ErP Directive — Redefining Energy Efficiency and Fan Technology for the Future

2025-10-24

-

High-End Equipment Cooling Solutions — AFL Fans Powering the Future of Precision Manufacturing

2025-10-24

-

High-Efficiency EC Fan Solutions for Data Centers — Precision Cooling, Reliability, and Energy Optimization

2025-10-24

-

Custom EC & AC External Rotor Fans for HVAC OEMs — Precision Engineering, 15-Day Delivery, and R&D Validation

2025-10-24

-

External Rotor Motor Fans for Continuous HVAC and Electronics Cooling

2025-10-17

-

AFL Motor — EC & AC Fan Manufacturer for HVAC OEMs: Custom External Rotor Fans, Fast Lead Time, ISO9000 Quality

2025-10-24

-

Solving Industrial Cooling: EC External Rotor Fan Technology Deep Dive

2025-10-11

-

Mastering Fan Selection: Backward Curved Centrifugal Fans and the Path to ERP2015 Compliance

2025-09-30

-

Energy Efficiency and Ultra Quiet Operation Revolutionizing Industrial Ventilation with EC Fans

2025-09-25

-

Next-Generation FFU & Data Center Fans: AFL’s Metal Centrifugal and EC/DC Solutions

2025-09-13

-

AFL External Rotor Fans Axial Fans in Fan Solutions for the Renewable Energy Industry

-

DC Backward Centrifugal Fans - AFL Fans Premium Solution for Industrial Ventilation

-

High-Quality DC Backward Curved Centrifugal Fans φ220 for Industrial Applications | Trusted Supplier in China

-

DC Backward Centrifugal Fans φ250 – High-Performance Industrial Fans

-

DC Backward Centrifugal Fans φ225 for Industrial and Commercial Use